Image credit: Kalika Studio

Our recent report titled “White Space #1: Sub-categories with limited innovation” covers the four currently under-served material categories of next-gen wool, silk, fur and down. Here, we look at the highlights from the next-gen wool section of the report: its market potential, what makes it special, how traditional wool can be improved upon, and the key targets material innovators should aim for. Stay tuned for our final post in this series covering next-gen down.

Download the full report for free to learn about white spaces, or see our summary. Wondering what we mean by white spaces in the context of next-gen materials? See this blog post.

Market Potential

The technologies used to create next-gen wool, acrylic, and polyester overlap, so entrepreneurs, investors, and innovators looking to recreate wool should also look to the acrylic and polyester markets, and vice versa, as part of the total addressable market. Acrylic was developed in the 1940s as a synthetic alternative to wool, designed to mimic wool’s desirable properties while being more affordable and easier to care for.

The acrylic fiber market is estimated at USD 2.7 billion in 2024, but is expected to decline to USD 2.4 billion by 2029, this could be due to strict global regulations on its production and the readily available alternative of polyester.

The global wool market size is expected to grow from USD 39 billion in 2024 to USD 49 billion by 2028.

Uniqueness: What makes wool so special?

Image credit: ettitude

Wool’s versatility spans from luxurious to utilitarian applications, with varying fiber lengths, textures, and colors derived from different animal origins. It offers contrasting hand feels, from super soft to coarse, and has become suitable for year-round wear. Coarser yarns provide a sense of protection, while cashmere evokes a luxurious feel.

Wool’s unique structure gives it exceptional performance properties such as insulation, moisture-wicking, odor resistance, durability, wrinkle resistance, flame resistance, and biodegradability, making it a multifaceted material with a deep-rooted emotional appeal.

Innovation Potential: How can wool be improved?

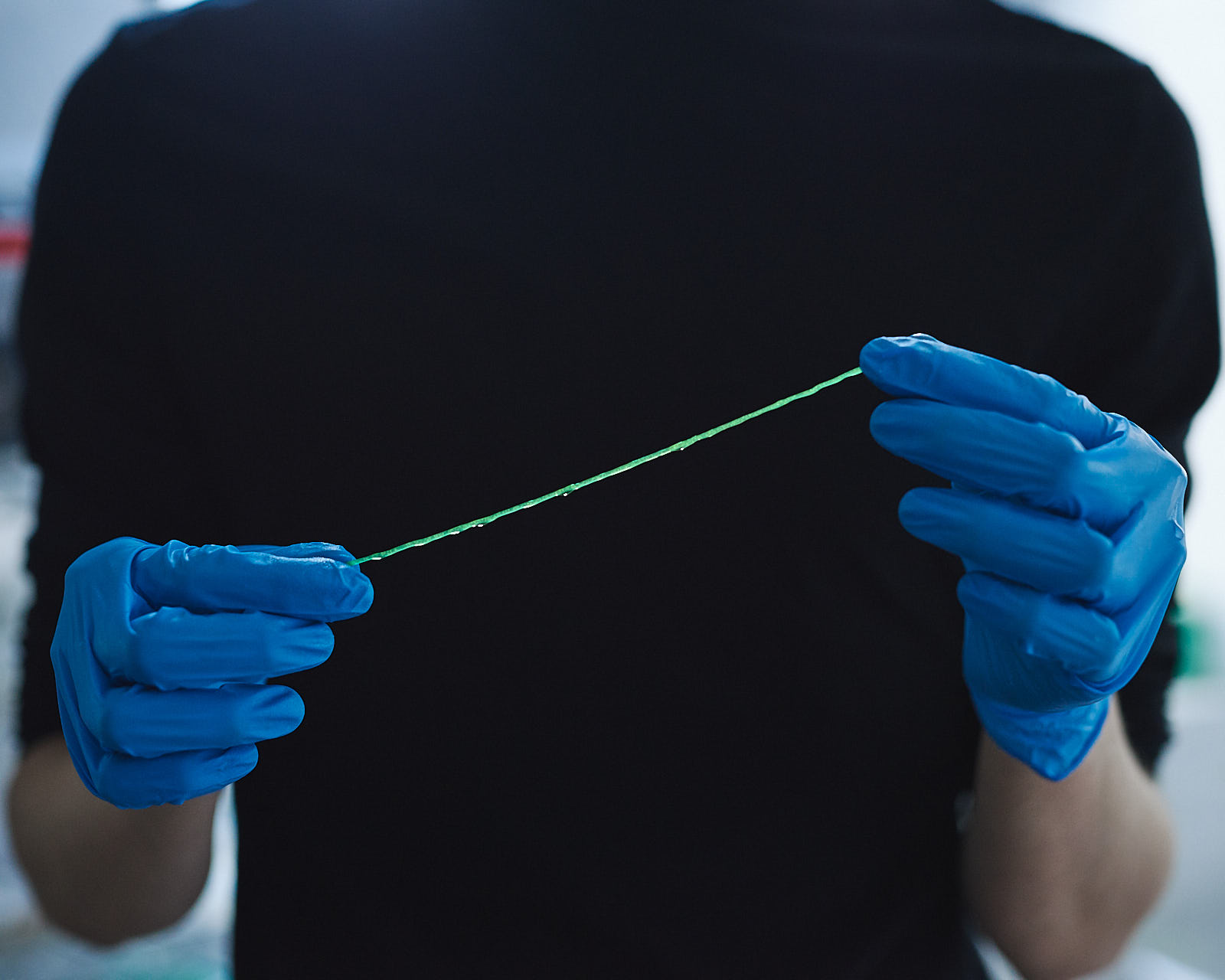

Image credit: Jon Brown (Photographer) x Werewool

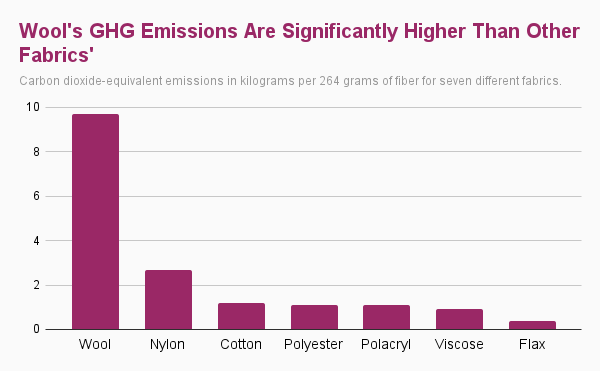

Wool faces numerous practical issues such as being scratchy, pilling, and requiring high-maintenance care. Wool also contributes to significant environmental issues such as high GHG emissions, water use, chemical use, and hindering biodiversity. Animal welfare issues, such as painful live lamb cutting (mulesing) and high lamb mortality and slaughter, persist. Next-gen alternatives offer the opportunity to mitigate or solve all of these problems.

Image Caption: One study’s estimate of greenhouse gas emissions per 264g of fiber for seven different fabrics. Study by Ecoinvent, original graph created by Vox.

See our blog post on the drawbacks of wool production here.

Key targets for creating wool alternatives

Image credit: KD New York

While next-gen wool should (by definition) have a lower environmental impact without the animal-cruelty, these factors alone are not sufficient for success. Next-gen wool must also meet the performance attributes of wool and be cost-competitive.

Wool can be improved upon in its next-gen realization across six key target categories.

Environmental Targets

Focus on key areas such as recycled or biobased material inputs, end-of-life considerations, mitigating microfiber release, green chemistry for additional components, and environmental impact reductions.

Tunability and Variety

It is critical for next-gen wool innovators to understand that to be successful they will need to offer a portfolio of yarns or finished textiles to brands. Animal-based and synthetic wools have a wide variety of colors, prints, patterns, textures, and lengths.

Eliciting Emotions

Wool products are known to appeal to human emotions and conjure up expectations – like warmth or protection. Focus on optimizing the qualities that affect our emotional responses, such as color, surface texture, drape and hand feel.

Wear, Care and Laundering

Anything that makes caring for a product—whether it is a blanket or apparel—easy and economical is a win for the consumer. Machine washability, lack of shrinkage and pilling are some key priorities here, among others.

A Variety of Applications

Wool, wool blends, and acrylic offer a wide range of options for diverse markets and uses, from home goods and furniture upholstery to apparel, footwear, and accessories. Innovators should explore these versatile applications while considering regulatory requirements like flame retardancy where necessary. Wool historically dominated the outdoor apparel market before the rise of acrylic and nylon, highlighting its enduring potential in this sector.

Brand and Manufacturing Partners

It is important to develop yarns that drop into the existing supply chain. Working with a brand is crucial to get feedback on various aspects of your materials in different applications. Also aim to work with a mill or textile manufacturer to ensure your yarn will work in the existing equipment and to help you troubleshoot common issues.

Download the full report: White Space #1: Sub-categories with limited innovation for in-depth coverage of next-gen wool and the other untapped materials in white space number one; you’ll also discover the material innovation companies that are currently working on next-gen wool.

Want to see some real-world examples of next-gen wool? Check out our monthly next-gen materials “lookbooks” to see the latest brand and material company partnerships.

Don’t forget to sign-up to our newsletter to be notified when the next report in our white space series is published.